漆と金属 / Urushi and Metals

ある物件の家具の面材として、パッと見た印象が、金属?と思うような漆の仕上げを計画しています。

漆の塗りの中で、金属の粉を蒔絵のように蒔く技法があります。

四分一塗りというのがその1つで、四分一粉という錫粉と炭粉を混ぜたモノを漆塗りの面に蒔く技法です。

金属の銅と銀の合金である四分一(銀の配合が四分の一であることから名付けられている)という金属に

似た塗りなので、このように呼ばれています。

粉の蒔き方や、漆と四分一粉の沈み具合で表情が変わり、そのなんとも言えない奥行き感がでて、

独特なテクスチャーになります。

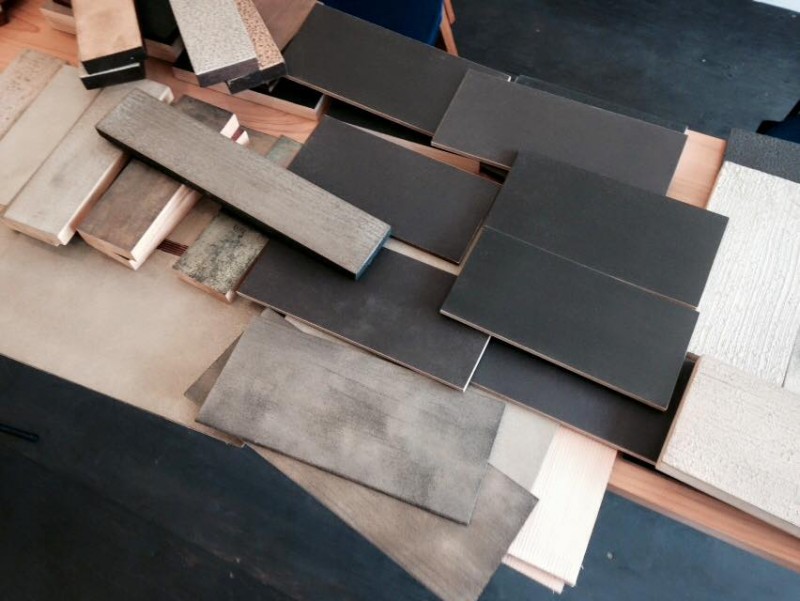

工房でサンプルを見ると、少しの配合や塗り方、下地の処理で色味が違っています。

広い面になればなるほど、蒔き方、研ぎ出し方、乾燥の時間などで見え方がかわり、管理がとても重要です。漆は経年変化をする素材なので、完成時の色合わせがとても難しく、それが楽しみでもあります。

いよいよ制作開始!真夏の工房での作業は本当に骨折る作業だと思います。

完成しましたら、こちらでご報告できればと思いますので乞うご期待を!